标准水泥生产线

Standard cement production line

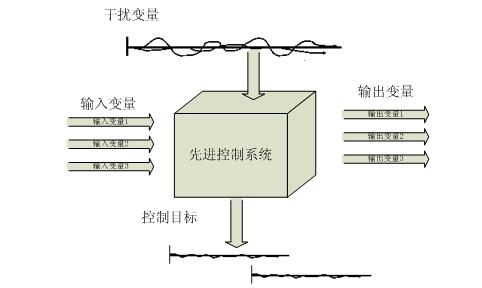

水泥先进控制系统采用了先进的人工智能技术,对传统控制无法解决的控制问题,能进行有效地控制,对稳定生产、节能降耗、提高劳动效率有突出的效果,其工作原理如下图:

Advanced cement process control system adopts advanced AI technology. As for control problems that traditional control cannot solve, the advanced cement process control system can make effectively control. It also can effectively stabilize production, save energy and reduce cost, and improve working efficiency. Its working principle is as follows:

分解炉出口温度自动-手动参数对比

Parameter comparison on auto and manual control of decomposing furnace outlet temperature

红色——喷煤量,蓝色——温度。

Red-injected coal rate, blue-temperature

绿色,浅兰色——自动预估值,黑色——设定温度值。

Green, light blue-auto discreet value, black-set temperature value

先进控制系统(烧成部分)含功能块:专家系统模块、分解炉温度控制模块、篦冷机控制模块、脱硝控制模块、综合优化模块等。

Advanced process control system (calcining) includes the following functional blocks: expert system module, decomposing furnace temperature control module, grate cooler control module, denitration control module, comprehensive optimization module etc.

1.2 协同垃圾处理

2.2 Collaboratively refuse handling

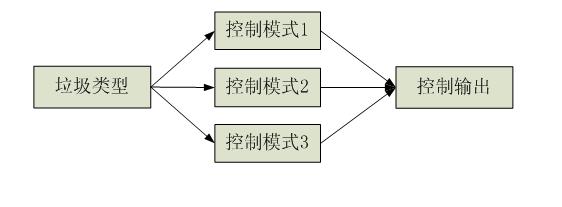

随着国家对垃圾处理要求的不断提高,水泥生产线协同垃圾处理,已经在国内多个生产线上投入实际应用,南京翰杰软件技术有限公司的水泥先进控制系统在水泥协同垃圾处理生产线上也得到了验证,并针对多种不同的垃圾处理作出了相应的功能模块。

With the continuous improving requirement on refuse handling, cement production line cooperate with refuse handling has been put into application in several production line in China. Advanced cement process control system of Nanjing Hanjie Software Co., Ltd is also proved in cement production line cooperate with refuse handling. In addition, it provides corresponding functional modules on different waste.

-

解决方案:水泥先进控制系统(HJAIC)生产管理系统(HJPMS)智能巡检系统(HJEIS)

-

能源管理系统(HJEMS)